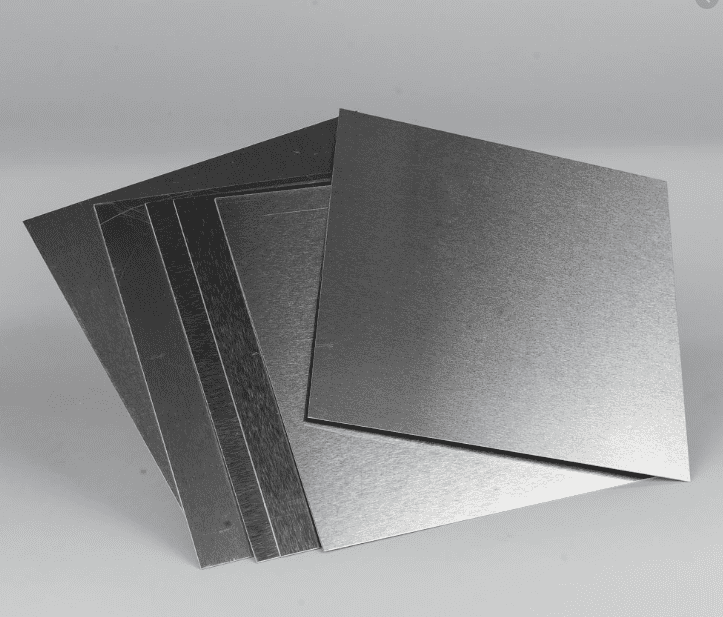

FLAT-ROLLED ALUMINUM

FULL-SERVICE ALUMINUM CAPABILITIES

From design to distribution, our extensive inventory of flat-rolled aluminum coils can be slit, cut-to-length (CTL), or sheared to meet your manufacturing requirements.

Our aluminum stock is available in the following formats:

- Mill Finish

- Painted

- Embossed

- Anodized

- Powder Coated

As a full-service aluminum products supplier and service center, American Douglas Metals (ADM) offers quality and reliability to exceed the needs of diverse industrial and manufacturing applications across the globe.

THE FLAT-ROLLING PROCESS

ADM has the highest quality, state-of-the-art production equipment that allows us to control the processing detail of each project with ease. Generally speaking, flat-rolled products are usually made by rolling thick aluminum between rolls to reduce the thickness and lengthen it. Our aluminum strip, coil, foil, rod, pipe, plate, sheet, and other profiles are produced in a facility created to service different rolling techniques and finishes for your project needs.

REQUEST QUOTES OR

ADDITIONAL INFORMATION

To speak with an American Douglas Metals (ADM) representative regarding our available products or services, please fill out the form below and we will contact you as soon as possible.

FLAT-ROLLING TECHNIQUES

Hot-Rolled

Hot rolling means that the sheet of aluminum is processed into a coil at a temperature of 1700 Fahrenheit. This allows it to become more malleable and easier to roll into a coil for storage, transportation, and later processing by the client company. Hot rolled aluminum has a higher surface quality which allows it to be best used for mechanical properties such as automotive building and creating industry-specific equipment.

Cold-Rolled

Cold-rolling products are processed similarly but include an added step to achieve a more exact dimension on the aluminum finish. After the aluminum has cooled down, it is run through the rolling mill once again to modify the surface area. Cold rolling creates a product that works best for projects that require smooth services, well-defined edges, and corners such as domestic appliances. The only downside to the production of this material is that it requires more pressure compared to hot rolling because the cooled aluminum is not as malleable.

Cold-rolling products are processed similarly but include an added step to achieve a more exact dimension on the aluminum finish. After the aluminum has cooled down, it is run through the rolling mill once again to modify the surface area. Cold rolling creates a product that works best for projects that require smooth services, well-defined edges, and corners such as domestic appliances. The only downside to the production of this material is that it requires more pressure compared to hot rolling because the cooled aluminum is not as malleable.

Our aluminum stock is available in the following formats:

OUR FLAT-ROLLING SERVICES

Mill Finish

Mill finish is the natural appearance of the aluminum as it comes from the rolling mill or extrusion mill. It is “as is” with no external mechanical or chemical finishing. Extruded metal is considered a “mill finish”. The finished products are generally very shiny in appearance and will contain mill marks from the extrusion process. All aluminum has an oxide of varying thickness, mill finish products should never be exposed for an extended period, since this may allow the metal to begin the oxidation process. Our capabilities allow us to properly store and offer transportation services to ensure that you receive your products in the highest quality possible.

Painted

Painted finished offers extreme durability in outdoor exposure as well as indoors because of our high-quality paint system. Pre-painted aluminum sheet finishes are uniquely designed in that they provide a hard, abrasive resistant coating, yet allow the flexibility for extensive forming and fabricating on an extrusion.

Embossed

Embossing refers to the creation of an impression of a design on raw materials. ADM utilizes this technique to create imprints on metal coils, sheets, and other metal fabrication materials as needed. It is used often to create industry-specific products such as aluminum automotive parts, create designs in a plate or foil, and many more. Embossed aluminum works well to disperse liquid more effectively, reduce friction and static, and increase metal surface area for heat transfer application.

Anodized

Anodized aluminum is processed into a decorative, durable, corrosion-resistant, anodic oxide finish. This process fully integrated with aluminum so it cannot peel or chip. It has a highly ordered, porous structure that allows for secondary processes such as coloring and sealing.

Powder Coated

Powder-coated finishes provide durability and a protective layer against moisture, scratches, and knocks. In addition, power coating adds a decorative color and texture to aluminum extrusions. At ADM we have a range of bright hues and unique textures for your aluminum application. Powder coating has the added benefit of being more environmentally friendly than liquid paint, which is an important factor to consider.

EXAMPLES OF FLAT-ROLLED PRODUCTS

Flat-rolled products, sheets, plates, and foil have made up the largest volume of aluminum products produced annually in the United States. Flat-rolled products have exceeded their demand for several industries such as construction, automotive, aerospace, technology, electrical, and so on. Thanks to our precision-based equipment, no job is too complicated.

As a full-service aluminum products supplier and service center, American Douglas Metals (ADM) offers quality and reliability to exceed the needs of diverse industrial and manufacturing applications across the globe.